Production

Consumption

Key benefits of predictive maintenance for critical assets

- Increase of asset lifespan: Proactive maintenance helps to identify and address minor issues before they escalate, extending the overall lifespan of your critical assets

- Reduced maintenance costs: Perform maintenance when it's truly needed, eliminating unnecessary interventions and associated costs

- Forecasting of water production & consumption: Prediction algorithm will predict the water consumption for future based on the past consumption data

- Improve citizen health: Continuous monitoring of water quality improves citizen health

- Reduce water wastage: Pressure, flow and leak monitoring will enable reduction of water wastage

- Enable remote monitoring and governance: Monitor all critical assets remotely, allows greater flexibility and responsiveness to changing conditions

- Virtual control actions: Minimizes the need for on-site personnel for routine maintenance and monitoring tasks managed from technology platform

- Reduced carbon footprint: Minimize environmental impact by decreasing reliance on fossil fuels and reducing greenhouse gas emissions

And more...

-

1 Continuous Monitoring and Readiness

Platform runs continuously and monitors the booster pumps round the clock

-

2 Initial Validation

Validation based on data correlation and AI-ML output

-

3 Event Detection

Based on AI/ML data, event is detected for potential water pump failure 15 - 21 days a head of time

-

4 Notification and Alert Dispatch

Notifications are sent to work order creation and communicate to relevant stakeholder

-

5 Real-Time Coordination

Working pump (potential detected failure) is moved out of sequence and standby pump is introduced

Work order is assigned to technician along with asset condition & potential spare parts

-

6 Incident Resolution

Technician will attend the maintenance task & complete the work order on or before stipulated time

-

7 Post-Incident Management

Once maintenance is completed, the pump is made primary in the sequence and measure the pump condition

-

8 Audit and Reporting

Platform manages all touch points and track changes for audit control purpose

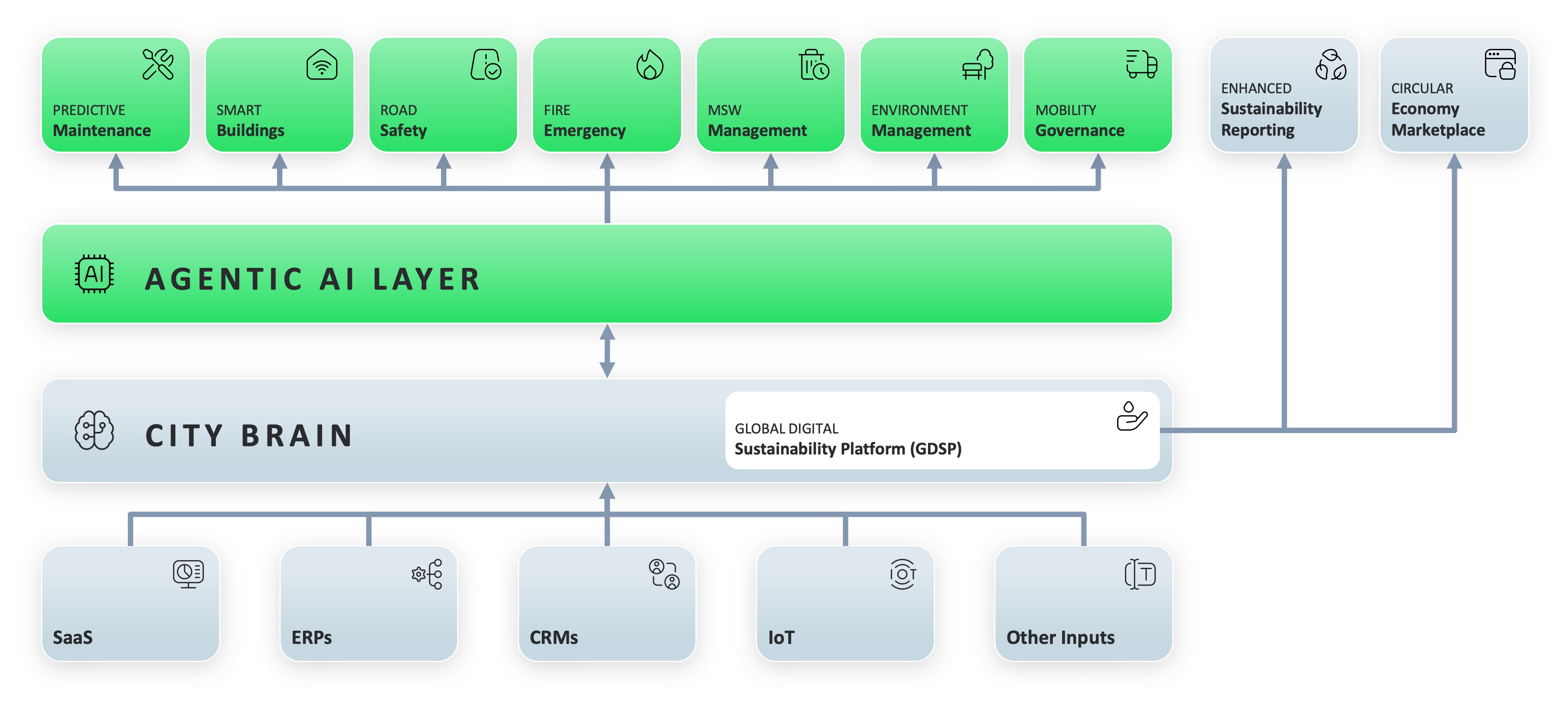

Global Digital Sustainability Platform

Global Digital Sustainability Platform

Enhanced Sustainability Reporting

Enhanced Sustainability Reporting

Circular Economy Marketplace

Circular Economy Marketplace

GDSP is integral to all Aramco Digital solution offerings

Key Success Factors

- In-kingdom locally hosted complying with strict cybersecurity requirements of the kingdom

- Comprehensive cluster addressing multiple segments of customers across the full value chain

- Integration flexibility - integrate with APIs to ERP solutions, GRC applications, EHS software, custom databases

- Custom data glossaries - address requirements across a broad range of sectors and industries.

- Custom standard libraries - enabling organizations to implement and monitor sustainability frameworks

- AI enabled insights - predictive analysis, forecasting and scenario modeling

- Dynamic compliance - adjust data models at source level to accommodate new regulations

- Transition to Business Sustainability Management (BSM) - scenario modeling and decision intelligence features

Key Success Factors

- In-kingdom locally hosted complying with strict cybersecurity requirements of the kingdom

- Comprehensive cluster addressing multiple segments of customers across the full value chain

- Market map - facilitate policy decisions, better visibility on materials price & demand

- Value chain traceability - necessitating informal players across the value chain

- Cross sector standardization - consistent material or product nomenclature across industries

- True market value - better visibility on market demand and price elasticity for all products & materials

Rotate your device for a better experience

Rotate your device for a better experience